MOULD CONSTRUCTION

Mass production of sheet metal, plastic and non-ferrous metal components, requires high- precision moulds, specifically made with high quality materials. It became obvious to Beoven TEC D.o.o that manufacturing its own molds allowed them to retain full control of the manufacturing cycle. Moulds are made by using the latest software technologies such as CAD and CAM. Besides manufacturing moulds for their own production needs, Beoven TEC offers the service of making them for third parties as well.

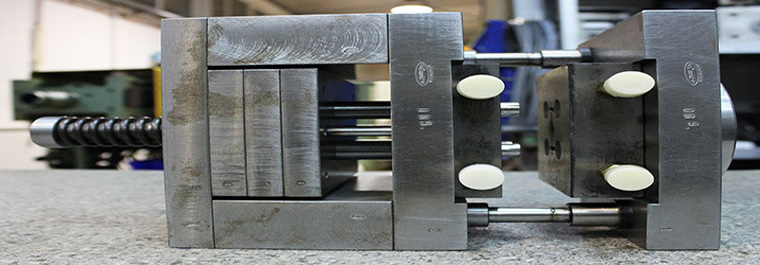

In the sheet metal sector, we also make moulds for punching, pressing, bending, etc. These moulds are fabricated using high resistant steel (up to more than 60 HRc). In the plastic sector, we make moulds for injection and for compression, as well as for blowing, thermoforming, extrusion and rotomoulding.

|